Mindesk, based in San Francisco (California) is part of Vection Technologies group (ASX:VR1) and develops a real-time 3D design platform made for an enterprise audience of designers, architects, engineers and CAD users. Mindesk lets users design projects from CAD through a proprietary VR interface with zero need for export. This revolutionary workflow also lets them switch between VR and desktop, editing and collaborating as they go. Mindesk now supports Varjo headsets.

Mindesk compatibility adds Varjo support to the popular SOLIDWORKS and Rhino3D CAD applications, Grasshopper algorithmic modeling tool, and Unreal Studio.

Gabriele Sorrento is a leading expert in Virtual Technologies applied to Computer Aided Design and co-founder of Mindesk, which he’s steering as CEO. We sat down with him to talk about how Varjo is helping to enhance their product experience with human-eye resolution, saving customers time, effort and money throughout the process.

Collaborative VR design in human-eye resolution

Mindesk changes the game for designers and engineers in two big ways.

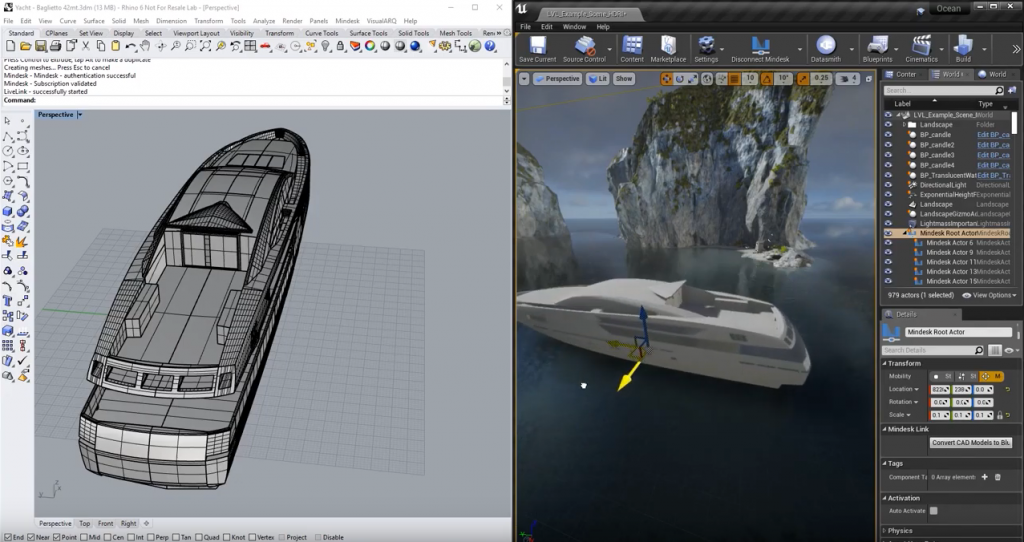

Firstly, Mindesk connects the source CAD software they already use to a VR environment in real-time, which removes the need for time-consuming file exporting-importing and 3D model processing, allowing them to work on models and collaborate with just a click of a button.

Secondly, Mindesk Live Link gives designers a real-time photorealistic view of a project as they model it, connecting existing graphic engines like Epic Game’s Unreal Engine and Rhino and saving all the conversion time along the way.

Ask any professional working in a VR environment what is the single most important requirement and you’re likely to get the same answer every time: resolution. Thanks to the compatibility with Varjo devices, designers can now work on CAD projects in VR with totally true-to-life fidelity through Mindesk. Just as if whatever they’re working on was already built and right in front of them.

“Varjo is fully activating the benefits that Mindesk provides to users. Designers need to see crisply all the details of a scene, all the curves and surface edges in all their sharpness, and Varjo delivers just that,” Sorrento says.

VR enables spotting almost twice as many issues than on-screen design reviews

VR enables spotting almost twice as many issues than on-screen design reviews

According to Sorrento, virtual reality already enables Mindesk customers do better work faster and way more effectively than ever before.

“Our users are realizing that real-time technologies are an essential part of their design process. By experiencing and modifying their projects in a 1:1 scale, they can spot more than 80% of the problems that go unnoticed when reviewing a project on a 2D surface.”

With traditional methods those mistakes tend to go amiss, found only after expensive processes. Many products even go into production with design flaws that could have been picked up during the design review phase. That generates sizeable cost overheads down the production and construction pipeline.

“VR is already being used to run way more flexible, efficient and collaborative design reviews that give everyone involved a clear and realistic picture of the design before it’s even built. And here too, the higher the resolution, the better,” Sorrento says.

“Varjo has an incredible resolution. For the first time ever you feel like there’s nothing between you and the virtual scene – you’re literally transported inside the CAD.”

Shorten design processes from years to months

There are some very concrete benefits to smoother, more efficient and more collaborative design processes, like shorter go-to-market times that need to become faster than ever in a competitive context.

“Companies can literally go from spending years on mechanical projects to just months,” Sorrento says.

He mentions one particularly sleek example. A naval designer, working for a renowned luxury yacht brand, was able to see and fix problems in the design instantaneously, delivering a ‘super yacht at a super speed’. This speedup resulted in the reduction in time-to-delivery and a higher customer satisfaction.

“In this example alone, we’re talking about a hundred thousand dollars in savings for prototyping,” Sorrento notes. The return on investment is glaringly obvious.

Remove the friction of physical models

Designers are very particular users who are all about the details. Every single tiny detail of the object they’re crafting is important to their customers. The luxury car industry as another example. Car designers need to get every single square millimeter right – every knob, every button, every screw needs to be just right.

This, Sorrento says, is where Mindesk and Varjo are able to deliver unprecedented value.

“There’s no longer any tangible barrier between what’s CAD and what’s real. The object you’re working on is so detailed that you can’t perceive any screen door effect. The VR model conveys all the visual sensations of a physical model, just without the physical restrictions that come with it,” he says.

Summing up: “Varjo gives a natural and realistic feeling, while Mindesk provides the professionality of the integration. Together, they remove the need for most physical models. Our solution can transport you into spaces that don’t exist yet.”

Varjo multiplies the amount of applications for virtual collaboration

Varjo multiplies the amount of applications for virtual collaboration

Now that Mindesk is able to deliver a seamless VR workflow that’s totally true to life thanks to Varjo’s human-eye resolution, what’s next? The Mindesk team is currently working with Varjo on the integration with Varjo’s mixed reality device. When asked about his personal first experience of Varjo’s mixed reality, Sorrento said this:

“My mind was blown away when I tried it. I’ve never experienced such a delightful XR experience in my whole life.”

Adding that Varjo is the only device that’s able to truly blend virtual and real, Sorrento sees massive potential for Mindesk customers.

“Varjo’s representation reconnects the digital world with the real one,” he says. And with hand occlusion and contextual lighting, Varjo opens a whole world of possibilities for collaboration and designing, testing and experiencing virtual objects in real-world environments.

“This is exactly what enterprise customers have been asking us for years. We are really proud to be finally able to deliver it through the partnership with Varjo, and we’re looking forward to creating the future that both of our companies dreamt of.”

Start working with human-eye resolution XR/VR

Meet the world’s only professional-grade VR and XR headsets, designed from top to bottom to allow industrial design professionals to work on projects where extreme precision and visual fidelity are needed.

VR enables spotting almost twice as many issues than on-screen design reviews

VR enables spotting almost twice as many issues than on-screen design reviews Varjo multiplies the amount of applications for virtual collaboration

Varjo multiplies the amount of applications for virtual collaboration